Car industry

Essential elements for the long-term cooperation in the car industry include innovativeness, reliability, flexibility, efficiency, traceability and process control and operation in accordance with IATF 16949. We provide our car industry clients mainly with solutions in the fields of:

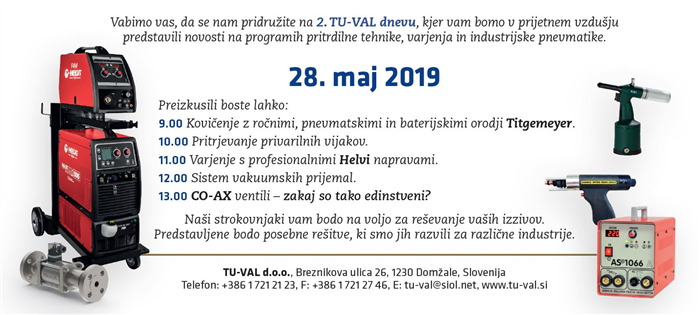

- Riveting process control

With the help of force gauges integrated in blind rivet fastening tools it is possible to control the riveting of each individual rivet. The results can be recorded in real time, while the system is capable of alerting on inconsistently riveted rivets, which helps to achieve 100% production reliability.

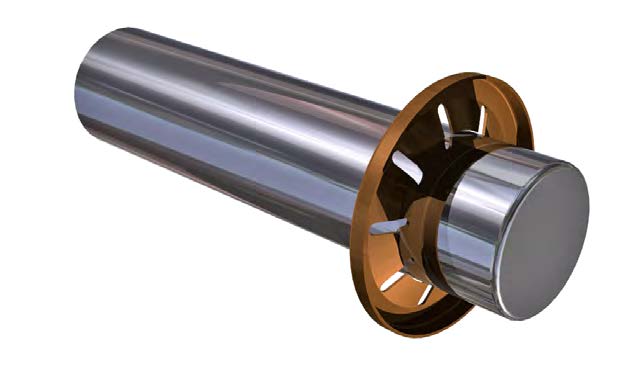

- Automatic insertion of axle guards

Starlock axle guards are one of the most efficient systems designed to confine the axle in its place. With the help of the automatic axle guard feeding and inserting device, the insertion process is accelerated by up to 50%.

- CNC welding of welding studs

Welding of welding studs, nuts, bushings and spacers can be a very efficient process, since it reduces the need for material drilling, screw insertion and the assembly, and also ensures a strong link between the material and the screw. We also provide process automation, which increases savings and raises the efficiency to the highest level.

- Robot riveting, riveting automation

The use of robots has spread to several repeating processes. Initially, we were providing our clients with production cells using with the help of industrial robots. Lately, it is possible to detect a growing use of collaborative robots in riveting processes. Fastening process for self-tapping screws, which are especially resistant to vibrations and achieve high shear strengths, is also suitable for automation.

- Clamping tools, grippers

Introduction of robots has also increased the needs to integrate robots into the production process. Therefore, an appropriate tool is required (End of Arm Tooling). It is our task to successfully construct these tools, select appropriate clamping elements – mechanical, pneumatic, hydraulic, electric or vacuum grippers, and to provide the optimal solution to our client.

- Manufacture of turned parts

We are talking about large product series – 100,000+ pieces annually. The price of basic material is very important – profiles made with custom-made tools, and direct purchase from the manufacturer. Technological solutions where the last seconds are squeezed out of the turning cycle combined with cleaning (e.g. 36mN/m) – testing of individual series, process reliability expressed in SPC or CPK and long-term contracts with the final user.

- Axle guards, screws, blind rivets, self-tapping screws, self-clinching fasteners and other fastening technology

Work with us

Apart from our partners and clients, our success can mostly be attributed to our excellent partner network of first-class suppliers of technical products for distribution and starting materials for production, and providers of various services. You are also kindly invited to check out our job vacancies and our offer for capital integration when selling the company.

Contact