Food industry

Because of our ability of processing stainless steel and other NSF-approved materials, we have also introduced numerous solutions in the food processing industry where contact with food is a particularly sensitive area, appropriate line cleaning, and high productivity due to faster processing.

- Mixing pumps

In this case, we were solving the problem on how to mix the concentrate with water because the fruit concentrate included large pieces of fruit. Together, we developed a vacuum pump that completely eliminated this problem. Technologies used: selection of NSF, FDA materials – made of synthetic materials, screw element material, appropriate adhesive, gaskets, CNC machining, assembly, testing device, selection of vacuum level.

Vacuum generators and transporters

To help generate vacuum, we offer a range of various vacuum generators operating on the Venturi principle. These generators include the simplest, practically indestructible pumps, as well as more complex electronically controlled pumps, which consume considerably less energy. Within this scope, we also offer vacuum transporters for the transport of seeds, pills, tablets, etc.

- Vacuum grippers

We are providing our more demanding customers with a set of unique solutions for the manipulation of cheese, transport of eggs, cans, cereal and, of course, packaging and manipulation of cardboard boxes. For this purpose, we use grippers made of various materials – natural rubber, silicon, Teflon, etc.

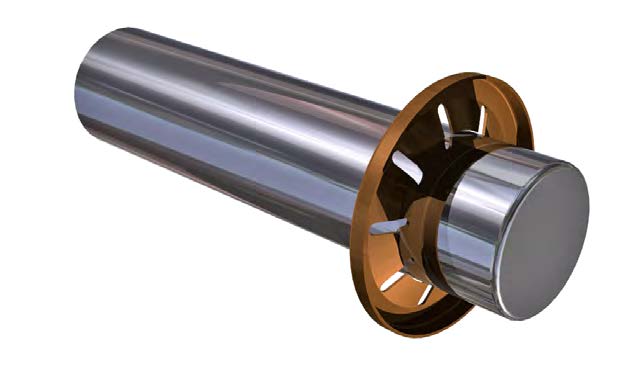

- Pneumatic cylinder, stainless steel

Technologies used: selection of the material for pipes and piston rods, CNC machining, welding in accordance with welding standards (ISO 3834; ISO 15614; ISO 9606; ISO 14732; ISO 5817 Level B; ISO 9712), life cycle test, marking, traceability, leak control.

- Stainless steel fittings

We offer various fittings made of stainless steel and also NSF-approved materials – standard threaded fittings, quick-release fittings, and quick-release clamps.

- Pressure gauges

In the food industry, it is very important to have control over the presence of the medium (milk, beer, water) and pressure, however, this has to be performed without coming into contact with this medium. For this reason, we can install pressure gauges and electronic pressure gauges using membrane technology. It this case, the medium is in contact with the material which can easily be cleaned, while the pressure indicating mechanism never comes into contact with the medium.

- Solenoid, manual process valves

We are looking for solutions in valves made of different types of stainless steel A1, A2, A4 – depending on the medium, temperature of the medium and the environment, pressure and other specifics of the project (ATEX, certificates, etc.)

- Press cylinders and valves

These products are used in the control of gas and liquids where medium is not allowed to come into contact with the product (live cultures, milk, and clean media). Manufacturing technologies – selection of profiles and materials for piston rods, CNC machining, sealing elements, sheet metal processing, assembly, testing and marking.

- Process valves and their parts

Valves made of different types of stainless steel, A1, A2, A4, 303, 316, 316L, duplex, Inconel, titanium. We manufacture the following valves or parts for ball valves, co-axial valves, solenoid valves, pneumatically controlled, manually controlled, flap valves.

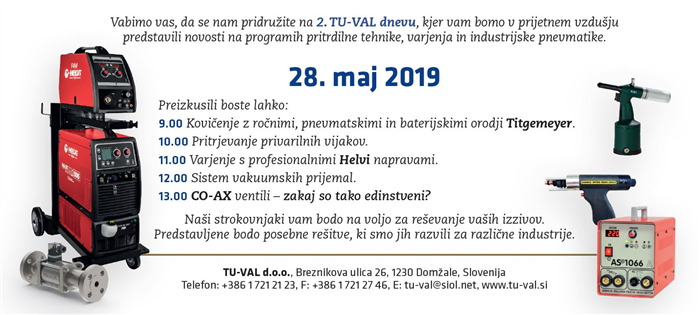

Work with us

Apart from our partners and clients, our success can mostly be attributed to our excellent partner network of first-class suppliers of technical products for distribution and starting materials for production, and providers of various services. You are also kindly invited to check out our job vacancies and our offer for capital integration when selling the company.

Contact